Brian Deltorre: I used to work together with my buddy, Steve Simqu. (You might recall Simqu’s Yamaha XS650 from issue Number 002). At the time, I was thinking about building a Triumph bobber. I showed him some pictures of different Triumphs I had saved, but he talked me into building a Yamaha XS instead. I ended up picking one up and started making a bobber out of it. I was in my thirties with little free time, so it ended up on the backburner.

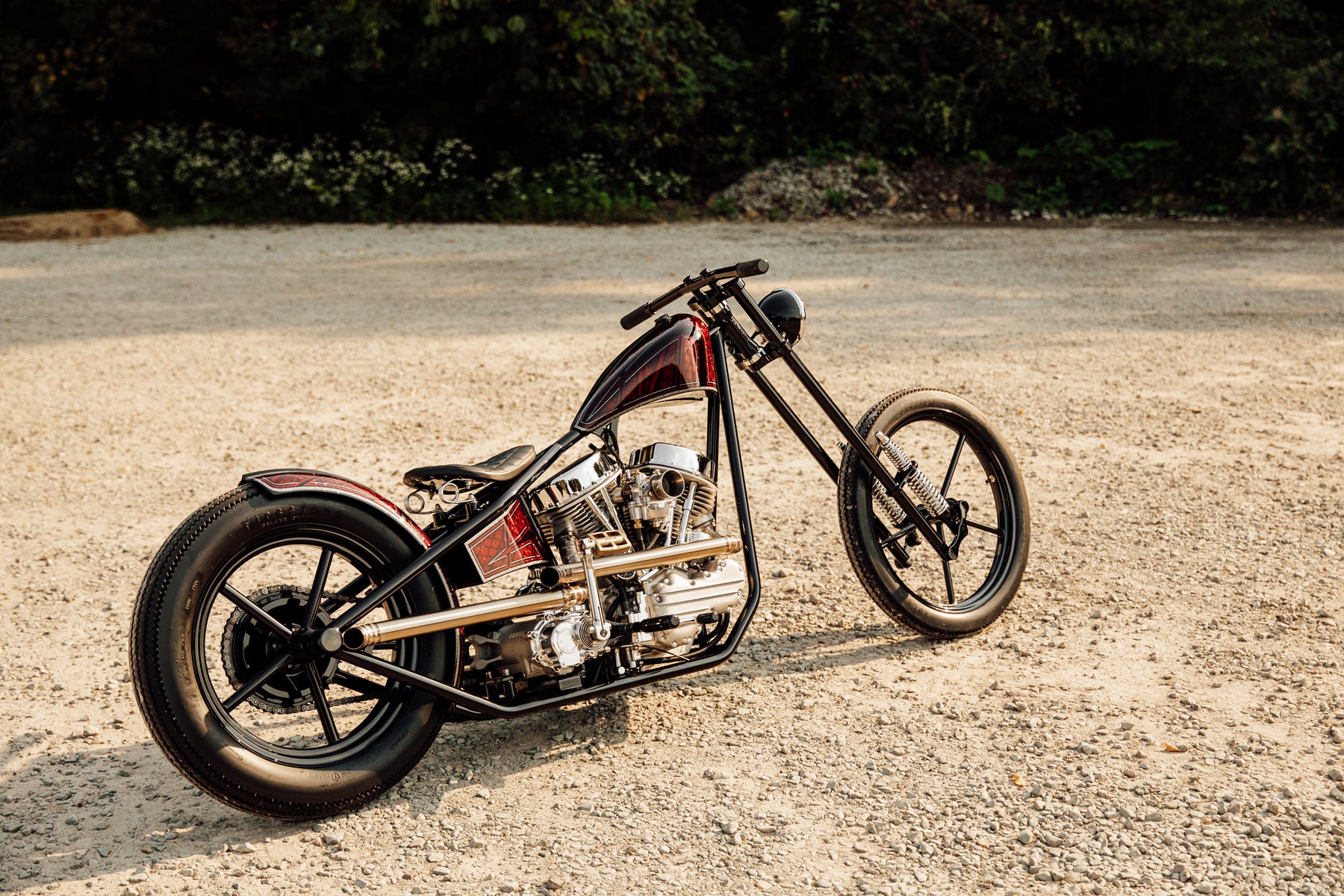

One day, my wife encouraged me to finish the bike, so I got to work and completed it in time to display at World of Wheels that year. At the show, a guy named Tony had a really nice bagger set up next to me and came over to ask who did the welding on my Yamaha. He needed some welding done for a project of his own, so we started bouncing ideas and skills off of each other. Tony mentioned, “When we’re done with this, why don’t we each build a bike for ourselves?” I told him to not pay me for the welding work I was doing then, but rather just pay for my materials on the bike build. We ended up getting roughly twenty-five feet of tubing and some prints before making a frame jig. We altered the prints to suit us, with this frame being 4-up and 2-out. All together we made three frames, two were mine, one was his. He went one direction with his build, and I went another with mine, chipping away at it a day or two a week.

BD: Yeah, it started as twenty feet of tubing. Tony bought a tubing bender, and we made the frame jig and some patterns that worked. The frame was the first piece I made for this bike, with the wheels being next.

BD: I’d say we probably started this in late 2017. Then two kids later, I finished it.

BD: The only Harley part on the bike is the headlight, and it’s from a Softail Blackline. I tried to make as many parts myself as possible and hide as many bolts as I could. I made the handlebars, pipes, and oil tank. The back fender was bought but reshaped. The exhaust started as six feet of tubing and consisted of thirty-three pieces.

When I was building my XS 650, everyone had a telescopic front end, so I put a girder front end on that to be different. For this bike, I wanted to do something I haven’t seen in a while, so instead of a regular springer, I made an inverted style. It works exactly the same as a normal springer front end, but all of the action takes place down low.

For the gas tank, I bought a huge six-gallon chopper tank that I cut up and reshaped for the look I wanted. I removed pieces of it, added pieces to it, and changed the radius on the bottom. The oil tank has the same radius as the gas tank.

BD: Panheads were always my favorite motors. I looked into getting an original but really wanted to hammer on this thing and avoid as many issues as possible. After some research, I ended up with the S&S P93 engine with a Baker 4-speed transmission. It just made sense. They’re bulletproof.

BD: It’s an internal twist clutch I picked up from Exile Cycles. This isn’t an ordinary 1970s style transmission. It’s a Baker to start, but I had it made with the 1990s ball and ramp style clutch actuator. Traditionally, the older style had an arm that came out of the top of the transmission, and when you squeezed your lever, the cable would pull the arm toward you. With this style, the cable goes into the transmission, so when you pull the cable, it moves that ramp with a simple twist action. It’s exactly the same as the internal throttle but twists the opposite direction for the clutch.

BD: Phil Williams of Bridge City Paint did the paintwork. I couldn’t decide on a color at first, but at the last minute, I chose red. When I went to Phil, I told him I’d like the tank to be symmetrical without being completely symmetrical. He knew exactly what I meant and did a great job. The underneath of the tank looks just as good as the top.

I’m using a fixed axle. So, instead of having the axle go through the frame and using a nut on one side, I built the nut into the frame. You screw the long axle and threads into the right side of the frame and use a set screw to lock it in.

BD: Along with those previously mentioned, Steve Simqu helped out a lot with this bike. We’d work on stuff in the evening until about 9pm, then go out to the local bar for a couple of beers. We’d get some good ideas while having those beers, then forget them by the morning.

BD: I’ve only gone to a couple of places with it so far. It goes in a perfectly straight line if I let go of the handlebars, so I’m happy about that. I’ll take it out sometimes when I get home from work, but I’m still giving it some shakedown miles for the time being.

I’m glad that I was able to build a lot of it myself. It typically costs more money to make your own parts because you have to make stuff to make stuff, but I’m proud that I was able to create so much on my own.